Hydroxypropyl Methylcellulose HPMC

Hydroxypropyl Methylcellulose HPMC for Gypsum Plaster

Hydroxypropyl Methylcellulose HPMC serves as an advantageous additive for enhancing the mechanical properties of gypsum plaster and various construction materials. Its role is that of an interface agent, which contributes to bolstering both the flexural strength of gypsum plaster and its bonding efficacy.

Hydroxypropyl Methylcellulose HPMC is a key component in the formulation of gypsum finishing plaster. This plaster variety is employed to attain improved wall leveling and a smoother overall surface texture. By harnessing the properties of HPMC, gypsum finishing plaster yields desirable results in terms of surface quality enhancement.

What is Gypsum Plaster?

Gypsum plaster is a notable white cementing substance produced through the process of partial or complete dehydration of the mineral gypsum. This mineral transformation is often coupled with the inclusion of specific additives, such as Hydroxypropyl Methylcellulose HPMC, which play a pivotal role in influencing the material’s properties.

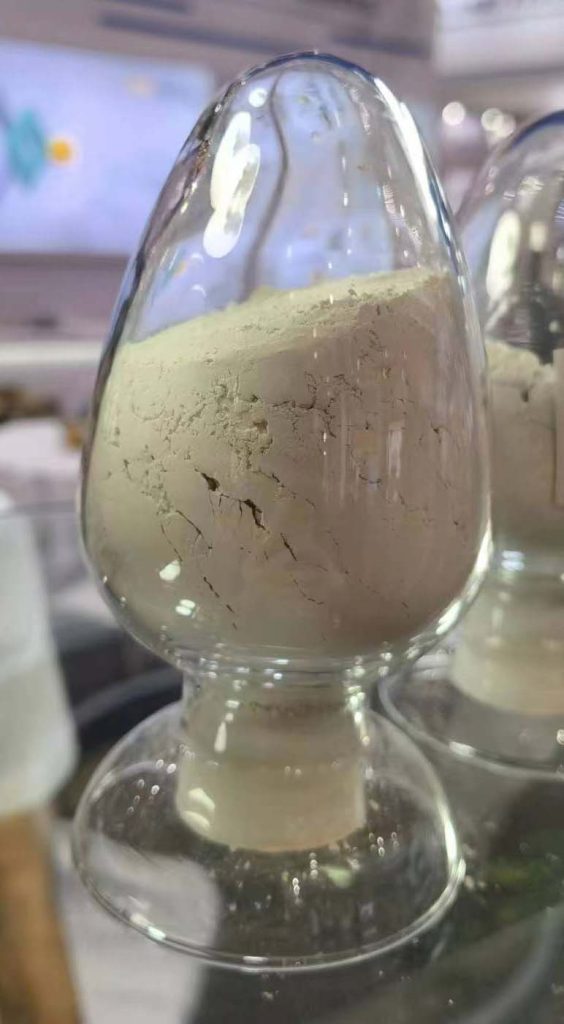

Hydroxypropyl Methylcellulose HPMC serves as a significant enhancer in the formulation of gypsum plaster. This compound, derived from natural polymer materials, undergoes a series of chemical processing steps to yield a non-ionic cellulose derivative. This derivative manifests itself as an odorless and non-toxic white powder, possessing several advantageous attributes.

When incorporated into gypsum plaster, Hydroxypropyl Methylcellulose HPMC functions as an interface agent, effectively augmenting the material’s tensile strength and bonding capabilities. It fosters an improved flexural strength within the gypsum plaster, thereby enhancing its overall mechanical integrity. Additionally, HPMC significantly contributes to water retention, thickening, emulsification, film formation, suspension, adsorption, gelation, surface activity, and its role as protective colloids.

Effects of Hydroxy Propyl Methyl Cellulose on Gypsum Products

The incorporation of Hydroxypropyl Methylcellulose HPMC into gypsum products yields a range of notable effects that significantly influence their properties and performance. These are few of the advantages manufacturers can get in incorporating Hydroxypropyl Methylcellulose HPMC into gypsum products.

Workability

The integration of Hydroxypropyl Methylcellulose HPMC into gypsum products yields noteworthy enhancements in terms of workability. By judiciously selecting the appropriate specifications of cellulose ether, which includes HPMC, the workability of plaster experiences a significant improvement.

Hydroxypropyl Methylcellulose HPMC is instrumental in providing gypsum plaster with a desirable consistency. This consistency imparts a pivotal role in the ease of application. The presence of HPMC ensures that the plaster maintains an optimal texture, rendering it conducive to smooth application and manipulation. This translates into a more efficient and seamless process of spreading and adhering the plaster onto the designated surfaces.

Water Retention

One of the key contributions of HPMC is its capacity to provide optimal water retention within the gypsum mixture. This attribute proves pivotal in ensuring that both the cement content and additional additives within the mixture undergo thorough hydration.

The presence of Hydroxypropyl Methylcellulose HPMC ensures that the hydration process is maximized. This is particularly valuable in extending the working time of the gypsum mixture. By promoting gradual and sustained hydration, Hydroxypropyl Methylcullulose HPMC effectively prolongs the period during which the mixture remains workable.

Hydroxypropyl Methylcellulose HPMC in water retention also significantly mitigates the risk of cracking in gypsum plasters. The sustained hydration supported by Hydroxypropyl Methylcellulose HPMC aids in minimizing the occurrence of premature drying and associated shrinkage cracks. This outcome is particularly significant in maintaining the integrity of the plastered surface, ensuring its long-term durability and visual appeal.

Adjust the Setting Time

As a versatile additive, HPMC can function as a set-retarder when introduced into these building materials. This set-retarder capability is particularly advantageous when specific construction timeframes are sought without the requirement for excessively extended curing periods. Hydroxypropyl Methylcellulose HPMC can influence the setting time of various construction materials, including those based on cement, gypsum, or lime.

Hydroxypropyl Methylcellulose HPMC ensures that the solidification process of the gypsum mixture is modulated in a manner that suits the intended application. By manipulating the concentration of HPMC, builders and manufacturers can finely tailor the setting time to match the operational requirements of the project. This adaptability enhances the practicality and versatility of gypsum-based construction materials.

Air Entraining

The addition of Hydroxypropyl Methylcellulose HPMC into plaster formulations results in the creation of minute air bubbles within the wet mortar. This air entrainment mimics a honeycomb-like structure within the material. These microbubbles act as effective lubricants, enhancing the overall construction performance of the plaster. This improved lubrication facilitates smoother application and manipulation, translating into more efficient and accurate plastering processes.

Hydroxypropyl Methylcellulose HPMC can induce air entrainment extend beyond the immediate construction phase. This effect contributes to several consequential benefits. One such advantage is heightened heat resistance, a factor of significance in construction materials. The presence of air pockets within the plaster assists in mitigating the transfer of heat, thereby contributing to improved thermal insulation properties.

The air entrainment facilitated by Hydroxypropyl Methylcellulose HPMC plays a role in enhancing sound insulation. The presence of air gaps within the plaster material contributes to its sound-absorbing properties, reducing noise transmission and enhancing the acoustic performance of the product. This is particularly relevant in settings where noise reduction is a priority, such as residential or commercial spaces.

Hydroxypropyl Methylcellulose HPMC Specifications

Hydroxypropyl Methylcellulose HPMC is typically encountered as a white or off-white powder, contributing to its visually neutral appearance. The light transmittance of Hydroxypropyl Methylcellulose HPMC is maintained at levels lower than 50%, a characteristic that aligns with its intended use as a construction and building material additive.

The viscosity of Hydroxypropyl Methylcellulose HPMC spans a range of 60000 to 800000 mPa.s. This viscosity parameter is essential in determining the material’s flow characteristics and behavior, particularly when integrated into various formulations. The precise control over viscosity enables the tailoring of Hydroxypropyl Methylcellulose HPMC to suit specific application requirements, especially in gypsum-based plastering.

The pH value of Hydroxypropyl Methylcellulose HPMC falls within the range of 5 to 8.5. This pH specification is reflective of the compound’s compatibility with various materials and environments, making it adaptable for integration into a wide array of formulations without adversely affecting their pH balance.

In terms of particle size, Hydroxypropyl Methylcellulose HPMC maintains a sieve residue of less than 5%. This parameter is indicative of the compound’s particle distribution and ensures that it possesses a finely powdered consistency. The water content of Hydroxypropyl Methylcellulose HPMC is kept below 5%, reflecting its stability and resistance to moisture absorption.

Uses of Hydroxypropyl Methylcellulose HPMC in Gypsum-Based Plastering

Hydroxypropyl Methylcellulose HPMC improves a lot of gypsum-based plastering, contributing to the enhancement of performance and end-results across different stages of the plastering process. These are the following gypsum products that utilizes Hydroxypropyl Methylcellulose HPMC:

Bonding Gypsum

Hydroxypropyl Methylcellulose HPMC is an essential component when it comes to bonding gypsum, especially in scenarios involving smooth or low suction backgrounds such as tiling, concrete, plasterboard, or surfaces that have been treated beforehand.

When applying gypsum to such substrates, Hydroxypropyl Methylcellulose HPMC plays a critical role in optimizing the adhesion process. These surfaces, characterized by their smoothness or low level of suction, pose a challenge in terms of achieving secure and durable bonding.

Hydroxymethyl Cellulose HPMC acts as a bonding agent that promotes enhanced adhesion by creating a bridge between the gypsum material and the substrate surface. The compound’s adhesive nature facilitates a strong and reliable connection, overcoming the limitations posed by the surface’s reduced suction or smooth texture.

Caulking Gypsum | Hydroxypropyl Methyl Cellulose

Caulking Gypsum is a specialized plaster composed of high-quality materials and formulated in treating seams, rectifying internal and external corners, and repairing minor damages within gypsum boards. In conjunction with joint tape, Hydroxypropyl Methylcellulose HPMC-rich caulking plaster offers a reliable and effective solution for seam treatment.

The inherent properties of Hydroxypropyl Methylcellulose HPMC contribute to the effectiveness of caulking plaster in gypsum applications. When introduced into the caulking plaster formula, HPMC enhances the overall cohesion and adhesion of the mixture. This property becomes particularly important when addressing seams, corners, and minor damages on gypsum boards, where a secure and lasting bond is crucial.

The inclusion of Hydroxypropyl Methylcellulose HPMC promotes the seamless integration of the caulking plaster with the gypsum substrate. Its adhesive characteristics ensure that the plaster adheres uniformly and securely, effectively sealing gaps, rectifying corners, and mending minor imperfections. The compound acts as a binding agent, creating a consistent interface that not only enhances the visual appearance of the gypsum boards but also reinforces their structural integrity.

Gypsum-Based Finish Materials | Hydroxypropylmethylcellulose

Gypsum-based and gypsum-lime plastering systems are characterized by their continuous application process, facilitated by plastering machines. These materials are renowned for their highly efficient and seamless coverage of walls and ceilings, achieved through the application of a single layer.

Hydroxypropyl Methylcellulose HPMC enhances the workability of the plaster mixture, ensuring smooth and consistent flow through the plastering machines. This improved workability is crucial for maintaining a continuous application process, enabling the plaster to be evenly and efficiently sprayed onto surfaces.

Hydroxypropyl Methylcellulose HPMC enhances the adhesion of the finish material to various substrates, resulting in a reliable and enduring bond. This characteristic is pivotal in ensuring that the sprayed plaster adheres effectively to walls and ceilings, providing a uniform and secure coating that contributes to the material’s longevity.