Polyethylene Wax

What is Polyethylene Wax?

Polyethylene wax is an ultra-low molecular-weight polymer derived from ethylene monomer chains. Its linear structure, high melting point, and low viscosity make it incredibly versatile for a multitude of industrial applications. This wax serves as a dispersant, slip agent, resin additive, and mold release agent.

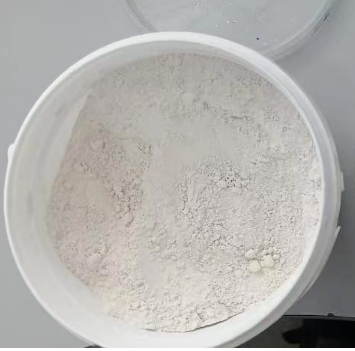

Polyethylene Wax,It is abbreviated as PE wax. Wax Powder is used in powder coating,master batch, road marking painting etc.

This wax proves indispensable as a raw material across diverse industries. It significantly contributes to the creation of coatings, cosmetics, PVC products, and inks. Its notable attributes include enhanced lubricity, dispersibility, and fluidity, rendering it a valuable addition to coatings, paints, inks, and similar formulations. PE wax enriches the final products by improving scratch resistance, gloss, and water resistance in coatings and paints. Its versatility extends to generating effects like extinction, dispersion, and smoothness, thereby elevating the overall quality of the end results.

What is Another Name for Polyethylene Wax?

Another name for polyethylene wax is PE Wax. Polyethylene Wax is also sometimes referred to as Polymerized Ethylene, High Density Polyethylene Wax, and Polymer Wax. It is a type of wax derived from the polymerization of ethylene monomers.

The chemical formula for polyethylene, the polymer from which the wax is derived, is (C2H4)x, where x represents the number of repeating ethylene units in the polymer chain. This formula illustrates the repeating structure of ethylene units that make up the polymer.

The CAS number or Chemical Abstracts Service number is a unique identifier assigned to chemical compounds. The CAS number for polyethylene wax is 9002-88-4. This is used in identifying and referencing the compound in various chemical databases and publications.

What is the Composition of Polyethylene Wax?

The quality and characteristics of polyethylene wax are influenced by several factors. These include viscosity, melting point, density, migratory capacity to surfaces, and color. Polyethylene wax from Tripletchem is commonly in white powder form and typically falls within a molecular weight range of 1000 to 2000. Its softening point spans from 95 to 115 degrees Celsius, and its density lies between 0.95 and 0.98 grams per cubic centimeter. Its viscosity at 140 degrees Celsius generally ranges from 10 to 40 centipoises, and the water content is maintained at less than 2%.

Polyethylene wax from Tripletchem is generated through distinct polymerization methods. High-pressure polymerization with oxygen-containing catalysts or low-pressure polymerization using chain-breaking techniques are the primary routes for its production. While polyethylene wax may possess lower strength and flexibility compared to other polyethylene forms, it demonstrates exceptional resistance to chemical substances and external pressures.

How are Polyethylene Waxes Made?

Polyethylene Waxes produced by Tripletchem are crafted through carefully orchestrated processes that ensure their specific properties and suitability for various applications. Tripletchem initiates the creation of pe wax by engaging in direct polymerization of ethylene. This intricate process is conducted under meticulously controlled conditions that play a crucial role in determining the molecular weight and chain branching characteristics of the final polymer.

Another method involves an alternative approach in the production of polyethylene wax Powder at Tripletchem. This method revolves around the thermal and/or mechanical decomposition of high molecular weight polyethylene resin. By subjecting the high molecular weight resin to carefully regulated thermal and mechanical processes, we are able to break down the resin into lower molecular weight fractions. This transformation yields pe wax with distinct properties that make it well-suited for diverse industrial applications like paints and coatings industry.

Why Are Polyethylene Waxes Used in so Many Applications?

Polyethylene waxes produced by Tripletchem find extensive utility across various applications due to their unique attributes and performance-enhancing characteristics. Here are just few of the characteristics that polyethylene wax gives to formulations.

Water-Repellent Properties

Polyethylene wax molecular structure is hydrophobic nature, causing water to bead up and roll off their surfaces. This property is particularly valuable in industries and applications where contact with water or moisture could compromise the integrity, durability, or performance of the end product.

In industries such as coatings, paints, and varnishes, the inclusion of polyethylene wax from Tripletchem helps create surfaces that are more resistant to water penetration. This, in turn, enhances the longevity and protective qualities of the coated materials, preventing potential damage caused by moisture exposure.

Prevent Pigment Agglomeration

Polyethylene waxes possess a unique property that facilitates the even distribution and stabilization of pigments within different mediums. When incorporated into formulations such as paints, coatings, and inks, these waxes act as effective dispersants. They help prevent the agglomeration or settling of pigments, which can lead to uneven coloring and reduced product quality.

The inclusion of polyethylene waxes improves the dispersion of pigments throughout the mixture of coatings and paints. This results in a more uniform color distribution, enhanced opacity, and improved coverage of the coated surface. The ability of these waxes to maintain consistent pigment dispersion leads to coatings and paints with superior visual appeal, ensuring that the intended color is accurately represented and achieved.

Influence Texture and Matting Effects

The application of polyethylene wax Powder is instrumental in achieving matting effects. These effects are particularly significant in industries like furniture manufacturing and wood coatings, where the aim is to create a non-reflective, matte finish. The addition of these waxes alters the surface properties of the final product, reducing light reflection and resulting in an elegant appearance.

Improves Anti-Scratch Capabilities

When incorporated into coatings, polyethylene waxes exist in the form of dispersed particles on the coating’s surface. It reduces the coefficient of friction of the coating. This reduction alters the dynamics of collision, where the inclination to slide becomes more pronounced than the inclination to scratch. As a result, the likelihood of scratches occurring on the surface diminishes, enhancing the overall durability of the coating.

Moreover, the incorporation of Polyethylene Waxes in coatings not only reduces friction-related challenges but also addresses issues like black marks that may arise from contact with other objects. The dynamic friction coefficient of a coating film can be decreased from 0.35 to 0.25 with this minimal addition.

Promotes Substrate Wetting

When coatings containing these waxes are applied to porous substrates, a process occurs wherein wax particles precipitate from the coating film. This phenomenon plays a crucial role in releasing gases that may have been adsorbed within the porous structure of the substrate.

Polyethylene wax Powder effectively prevent the occurrence of surface defects, such as blisters or bubbles, which could compromise the overall quality and appearance of the coated product. This gas release mechanism is particularly relevant in applications such as automotive coatings, where a flawless finish and adherence to porous surfaces are of utmost importance.

Polyethylene wax aids in achieving uniform and consistent wetting of porous substrates. This results in improved adhesion between the coating and the substrate, ensuring that the coating adheres evenly and effectively. This property is especially crucial in industries like woodworking and construction, where coatings must adhere firmly to porous materials.

Elevate Surface Smoothness and Texture

The application of polyethylene wax contributes to the creation of coatings with enhanced smoothness. The presence of these waxes on the surface helps in reducing surface imperfections, such as unevenness, roughness, or blemishes. It can transform the feel of a coating film, resulting in surfaces that are velvety, sleek, and inviting to touch. When polyethylene wax Powder is incorporated into coatings, it imparts a surface texture that is both visually pleasing and tactilely satisfying.

Increase in Extrusion Yield

The addition of even a small percentage of polyethylene wax can yield substantial increases in extruder yield. The incorporation of just 1% of micronized wax can lead to an impressive extruder yield enhancement ranging from 5% to 25%. This boost in extrusion output is significant for industries that rely on high-volume production and demand consistent, efficient processes.

The positive influence of polyethylene wax on extrusion output is particularly crucial in industries such as plastics and polymers manufacturing. The enhanced extrusion yield directly contributes to increased production capacity, reduced production costs, and improved overall operational efficiency. The reduced screw torque achieved through the inclusion of these waxes minimizes wear and tear on extruder components, further contributing to longer equipment lifespan and reduced maintenance needs.

How to Add Polyethylene Wax in Your Formulation?

When using polyethylene wax, it is typically introduced into formulations at a dosage of 1-3%. This percentage is based on the total weight of the formulation and is tailored to achieve the desired properties without adversely affecting the final product. The addition of polyethylene wax is generally done prior to the extrusion process. By adding the polyethylene wax Powder before extrusion, it becomes homogeneously distributed within the formulation.

In the case of micronized wax, the approach to addition differs slightly. Micronized wax can be incorporated into formulations both before and after the extrusion process. When adding micronized wax before extrusion, it is crucial to determine the optimal dosage, usually less than 1% of the total formulation. This small amount is sufficient to achieve excellent results, as micronized wax has a high surface area and enhanced dispersibility, leading to effective performance even at low concentrations.