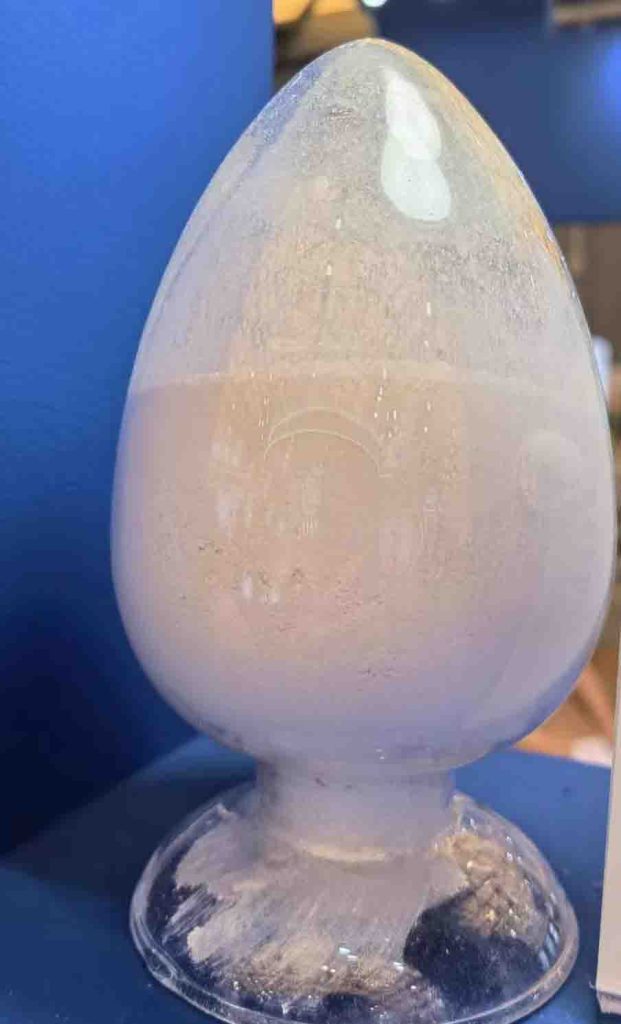

Hydroxy Propyl Methyl Cellulose HPMC

HPMC Hydroxypropyl Methyl Cellulose Ether Powder

The addition of hydroxy propyl methyl cellulose to self-leveling mortar formulations serves to regulate the water-holding capacity of the ground surface once the mortar is poured. This results in diminished and less conspicuous bleeding during the initial stages, subsequently leading to heightened ground strength upon drying. The inclusion of hydroxy propyl methyl cellulose also contributes to reduced shrinkage, which in turn plays a crucial role in minimizing the occurrence of cracks in the finished surface.

Self-leveling mortar serves the purpose of leveling and smoothing uneven concrete or subfloor surfaces before the installation of flooring materials. This technique is characterized by its advanced nature, as it naturally levels the entire floor with minimal intervention by construction personnel. This approach greatly enhances both the flatness and the speed of construction compared to traditional manual smoothing methods. Ultimately, the primary goal of self-leveling mortar is to create a flat, even, and smooth floor surface, preparing it for the subsequent installation of flooring materials.

What is a Self-Leveling Mortar? | Hydroxypropyl Methylcullulose

As mentioned above, a self-leveling mortar is a specialized construction material used to create flat and smooth surfaces on floors, correcting any initial defects or unevenness that might be present. It falls under the category of polymer-modified cementitious materials and is designed to achieve high-compressive, smooth, and level surfaces. This type of mortar offers several unique attributes that make it an ideal choice for certain applications, particularly when compared to traditional mortar mixtures.

The primary purpose of self-leveling mortar is to rectify unevenness or irregularities on floors, creating a smooth and level substrate for various types of flooring materials to be applied on top. Unlike regular mortar, which requires meticulous manual leveling and smoothing by construction workers, self-leveling mortar offers a more efficient and streamlined solution. Once mixed and applied, the unique flow properties of self-leveling mortar enable it to automatically spread and settle into a level surface under the influence of gravity. This property significantly reduces the need for extensive manual intervention and ensures a more uniform surface across the entire floor area.

Polymer modification in self-leveling mortar imparts improved performance characteristics, including enhanced adhesion, flexibility, and resistance to cracking. These properties make the mortar more durable and capable of withstanding the stresses and movements that floors can experience over time. Additionally, the polymer-modified nature of self-leveling mortar contributes to its rapid setting and curing times. Depending on the specific formulation and environmental conditions, self-leveling mortar can achieve its desired level of hardness and readiness for further construction activities within a relatively short time frame.

Self-Leveling Mortar VS Cement Mortar | Hydroxypropyl Methylcellulose HPMC

Self-leveling mortar is a pre-prepared mixture that comes ready for use, requiring the addition of water before direct application. This type of mortar is specifically designed to create surfaces that are both flat and smooth. It is characterized by its remarkable flowability, which enables it to automatically spread and level itself across a surface under the influence of gravity. This flowability is a significant advantage, particularly when dealing with large floor areas that need to be leveled quickly and efficiently.

Self-leveling mortar is formulated with hydroxy propyl methyl cellulose HPMC to achieve a compressive strength comparable to or even higher than that of conventional cement mortar. It is often used as an underlayment or topping layer on floors, providing a level substrate for the installation of various flooring materials. This mortar type is particularly advantageous when a smooth and even surface is essential, such as for tile, carpet, or other types of floor coverings.

Unlike self-leveling mortar, it is typically stiffer in nature, requiring more effort to spread and level across a surface. Cement mortar is widely used in various construction applications, including brick or block laying, plastering, and masonry work. Cement mortar offers excellent adhesion and durability, making it suitable for applications where load-bearing capability and structural integrity are paramount. It forms a strong bond with masonry units, creating solid structures.

HPMC Specifications for Self-Leveling

Hydroxy propyl methyl cellulose intended for self-leveling applications is characterized by its appearance as a white or off-white powder. Its moisture content is limited to less than 5% to maintain the stability and shelf life of the powder. The viscosity of hydroxy propyl methyl cellulose in a 2% solution should be capable of producing a viscosity within the range of 90,000 to 100,000 mPa.s (millipascal-seconds).

The gel temperature of hydroxy propyl methyl cellulose at 60% forms a gel-like structure in a solution influences the behavior of the self-leveling mortar during application, curing, and drying processes. The pH value of the hydroxy propyl methyl cellulose falls within the range of 5.0 to 8.5. It has a hydroxyl propyl group content ranging from 9% to 12 that influences the polymer’s solubility, adhesion, and overall functionality within the self-leveling mortar formulation.

What You Can Expect from HPMC Additives in Self-Leveling Mortar

Hydroxymethyl Cellulose additives bring several valuable attributes to self-leveling mortar formulation in enhancing the overall performance of the mortar. These are the following advantages of adding hydroxy propyl methyl cellulose in self-leveling mortar formulations.

HPMC Prevent the Slurry from Settling and Bleeding

Settling and bleeding are common challenges encountered in construction materials, especially in self-leveling mortars. Settling refers to the tendency of solid particles to sink to the bottom of a mixture over time, resulting in uneven distribution and inconsistency in the composition. Bleeding, on the other hand, involves the separation of excess water from the mortar mixture, leading to the accumulation of water on the surface and potential issues such as reduced strength and adhesion.

Hydroxy propyl methyl cellulose additives effectively address these issues by imparting stabilizing properties to the self-leveling mortar. When hydroxy propyl methyl cellulose HPMC is introduced into the mortar formulation, it creates a network-like structure that holds the solid particles in suspension and inhibits settling. This ensures that the mixture remains homogenous and uniform, allowing for consistent properties and performance across the entire floor surface.

The presence of hydroxy propyl methyl cellulose in the self-leveling mortar minimizes bleeding by modifying the rheological behavior of the mixture. The hydrophilic nature of hydroxy propyl methyl cellulose facilitates water retention within the mortar, reducing the risk of excess water separation. This contributes to improved cohesion, adhesion, and overall strength of the mortar.

Hydroxypropylmethylcellulose Controls Water Retention Capacity

Hydroxy propyl methyl cellulose additives controls the water retention capacity of self-leveling mortars. When hydroxy propyl methyl cellulose HPMC is incorporated into the mortar mixture, it forms a gel-like network that effectively traps and holds water molecules. This network structure slows down the evaporation of water from the mortar’s surface, extending the duration during which the mortar remains workable.

HPMC Reduce Mortar Shrinkage

A common concern in cementitious materials like mortar is the volume reduction that occurs as the mortar dries and cures. Shrinkage can lead to surface cracks, compromised adhesion, and unevenness, impacting the overall appearance and performance of the self-leveling mortar.

Hydroxy propyl methyl cellulose additives in self-leveling mortars enhances the structural integrity, appearance, and durability of the finished surface, ultimately leading to a high-quality and reliable self-leveling mortar application. By controlling moisture loss and shrinkage, hydroxy propyl methyl cellulose contributes to a smoother, more consistent, and longer-lasting result.

Hydroxypropyl Methylcellulose HPMC Avoid Cracks

The occurrence of cracks in cementitious materials like mortar can be attributed to various factors, including shrinkage during drying, stress due to temperature changes, and inadequate adhesion between the mortar and the substrate. Cracks can mar the appearance of the finished surface.

When hydroxy propyl methyl cellulose is incorporated into the self-leveling mortar mixture, it imparts improved water retention capabilities to the formulation. This controlled water retention slows down the drying process and reduces the risk of rapid moisture loss, which is a significant contributor to the development of cracks. By maintaining a more consistent moisture level within the mortar, hydroxy propyl methyl cellulose HPMC helps to alleviate the stresses that can lead to cracking. A crack-free surface is less likely to require frequent repairs and maintenance, leading to cost savings and fewer disruptions in the long run.

HPMC High Adhesion Strength

Hydroxy propyl methyl cellulose additives are incorporated into self-leveling mortar formulations to improve adhesion strength. The inclusion of hydroxy propyl methyl cellulose in the mortar mixture enhances its ability to adhere to various substrates, including concrete, wood, and tiles. This improved adhesion strength ensures that the self-leveling mortar bonds effectively to the underlying surface, reducing the risk of delamination or failure over time.

Hydroxy propyl methyl cellulose HPMC additives contribute to the workability and flow properties of self-leveling mortar. The presence of hydroxy propyl methyl cellulose enhances the mortar’s rheological characteristics, allowing it to maintain a consistent viscosity and flowability. This results in a more fluid mixture that can easily spread and self-level, ensuring even coverage over the surface. The controlled flow also reduces the need for excessive manual intervention during application, which can lead to a smoother and more efficient installation process.

This is a chemical product worth trying out. The use of this product in the production of latex paint putty, cement, tile adhesive, etc. will comprehensively improve the newcomers. It will not disappoint your expectations, and it is worth trying and using.

Hydroxy Propyl Methyl Cellulose powder is a critical ingredient in self-leveling mortar formulations. In the context of self-leveling mortar, hydroxy propyl methyl cellulose fulfills an indispensable role, yielding significant improvements in the water retention, fluidity, and lubricity of building materials. Cellulose ethers with low viscosity find extensive application in self-leveling formulations.