Hectorite Organoclay | Bentonite Performance Minerals

Hectorite organoclay exhibits a higher swelling capacity compared to bentonite organoclay. This means that when Arcilla Hectorita comes into contact with water or other compatible fluids, it can expand and retain a larger volume of the liquid. This enhanced swelling capacity is particularly advantageous in applications where fluid retention or controlling fluid behavior is crucial. That’s why hectorite organoclay cost a little more than bentonite organoclays.

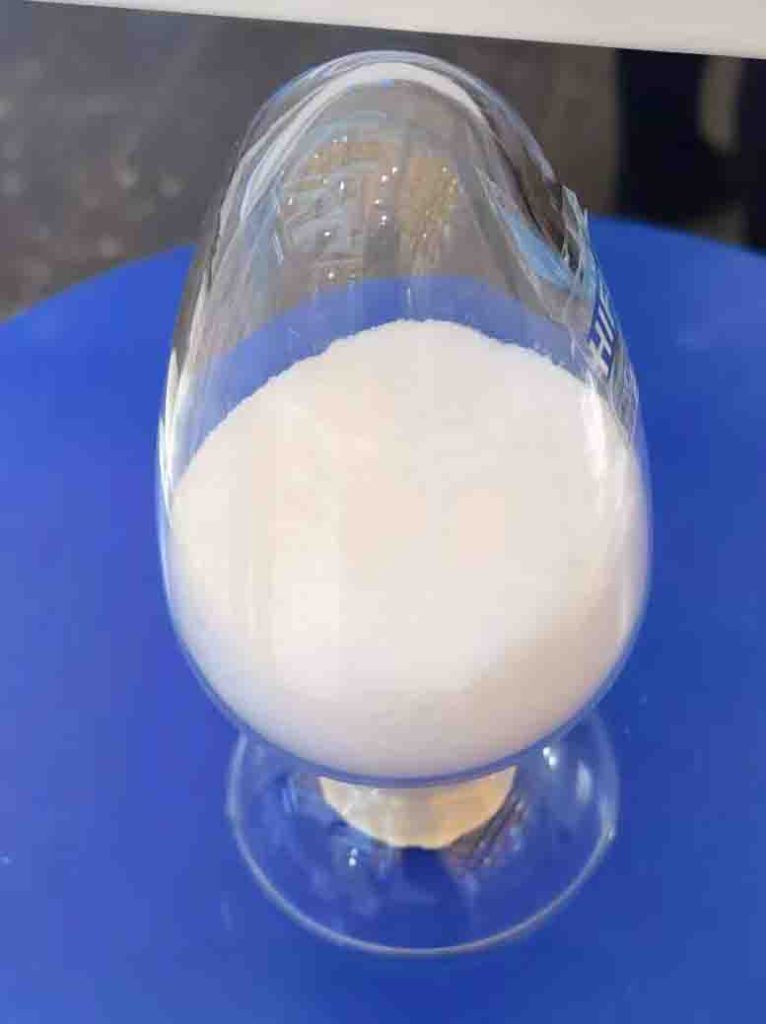

Hectorite-based products typically possess greater viscosity, meaning they offer better thickening and rheological control. It is free from crystalline silica, a mineral that poses health risks when inhaled. This absence of crystalline silica in hectorite-based products ensures a safer working environment and reduces potential health hazards associated with its use.

Hectorite: Synthesis, Modification, Assembly and Applications

Hectorite organoclay has an interesting origin that dates back to its discovery and description in 1941. The clay was named hectorite after an occurrence near Hector in the United States, where it was initially identified.

The formation of hectorito occurs alongside bentonite, another well-known clay mineral. These two clays often coexist, and their origin can be traced back to similar geological environments. The volcanic ash and tuff serve as the primary sources for the precursor minerals, and through various chemical reactions and changes in environmental conditions, clinoptilolite transforms into Arcilla Hectorita.

Synthesis and Modification

The synthesis and modification of hectorito involve several methods and techniques that enable the tailoring of its properties for specific applications. Hydrothermal synthesis involves subjecting specific reactants to high temperatures and pressures in an aqueous solution, mimicking the geological conditions under which hectorite naturally forms. This method allows for the controlled formation of hectorite crystals with desired properties.

Melt synthesis involves heating and melting the precursor materials to create a molten state, followed by cooling and solidification to form hectorite. This process is particularly useful for producing large-scale quantities of Arcilla Hectorita and can be modified to incorporate additional components into the final product.

Structure-directed synthesis focuses on the design and control of the crystal structure of hectorite through the manipulation of synthesis parameters and the use of specific templates or additives. By carefully selecting the precursor materials and employing specific techniques, researchers can influence the crystal structure and properties of the resulting Arcilla Hectorita.

Assembly

Layer-by-layer assembly involves the sequential deposition of different materials onto the surface or interlayer of functionalized hectorite. This process utilizes the opposite charges or complementary interactions between the hectorito organoclay and the other molecules or nanomaterials. Each layer is deposited one at a time, resulting in a multilayered structure.

Template assembly involves the use of a pre-existing template or scaffold to guide the assembly of functionalized hectorite and other components. The template can be in the form of a nanoparticle, nanofiber, or even a biological structure. Functionalized hectorite organoclay and other materials are assembled around the template, following its shape and structure. Once the assembly is complete, the template can be removed, leaving behind a nanocomposite with a defined structure and composition.

Hectorite Organoclay as Oilfield Chemical for Oil Drilling Mud

One of the key advantages of hectorito organoclay in oil drilling mud is its excellent solids-carrying capacity. When added to oil-based drilling fluids, hectorite organoclay significantly enhances the fluid’s viscosity. This property is particularly valuable as it facilitates the suspension and transportation of solid particles within the drilling fluid. The improved solids-carrying capacity of the drilling fluid helps to maintain a stable and effective drilling process, ensuring efficient drilling operations.

Hectorite organoclay exhibits excellent rheological properties, allowing for better control and management of the drilling fluid’s viscosity. This attribute is crucial in oil drilling, where maintaining the desired viscosity is essential for proper hole cleaning, cuttings removal, and overall drilling efficiency.

Hectorite Organoclay for Water Borne Paints

Hectorite organoclay is a valuable additive in water-borne paints. Hectorite organoclay has the ability to mix easily with oil and alkyd paints, enabling the enhancement of viscosity. By using Bentonite organoclay into these paint formulations, the viscosity can be increased, leading to improved flow and leveling characteristics during application. The increased viscosity also contributes to better control over the paint’s rheological properties.

Clay-based thixotropic agents like hectorite organoclay find suitability as suspension agents in nail polish formulations as well. The incorporation of hectorite organoclay into nail polish helps prevent the settling of pigments and other solid components. This property is particularly important as it reduces the risk of pigment sedimentation and syneresis, ensuring that the nail polish remains consistent in color and texture over time. By maintaining a stable suspension, Arcilla Hectorita organoclay enhances the overall quality and shelf life of nail polishes.

Hectorite Organoclay for Solvent Based Paints and Coatings

The versatility of hectorita organoclay extends beyond its role as a rheology modifier and stabilizer. It can also provide additional functionalities depending on the specific formulation requirements. For example, Bentonite organoclay can act as a thixotropic agent, allowing for precise control over the viscosity and shear-thinning behavior of the paint or coating. This property facilitates ease of application and ensures optimal coverage on different surfaces.

Targeting High Pressure, High Temperature Drilling

The use of Bentonite organoclay becomes essential in high-pressure, high-temperature drilling operations where wells exhibit higher temperatures or pressures above the norm. In these difficult circumstances, hectorita organoclay is essential for preventing formation damage and guaranteeing the success of drilling operations.

The drilling fluid’s capacity to regulate the swelling of clay minerals is one of the primary needs for drilling in high-pressure, high-temperature settings. An unstable wellbore, less effective drilling, and possible formation damage may all be caused by excessive clay mineral swelling. Hectorita organoclay appears to be quite useful in this area.

The swelling of the clay minerals contained in the drilling fluid is effectively controlled by the inhibitory characteristics of hectorite organoclay. Bentonite organoclay may help operators maintain the necessary rheological characteristics and stability while lowering the danger of formation damage. Arcilla Hectorita’s controlled swelling ensures that drilling operations go smoothly and reduces the risk of wellbore collapse or other negative impacts. This helps to maintain the wellbore’s integrity.