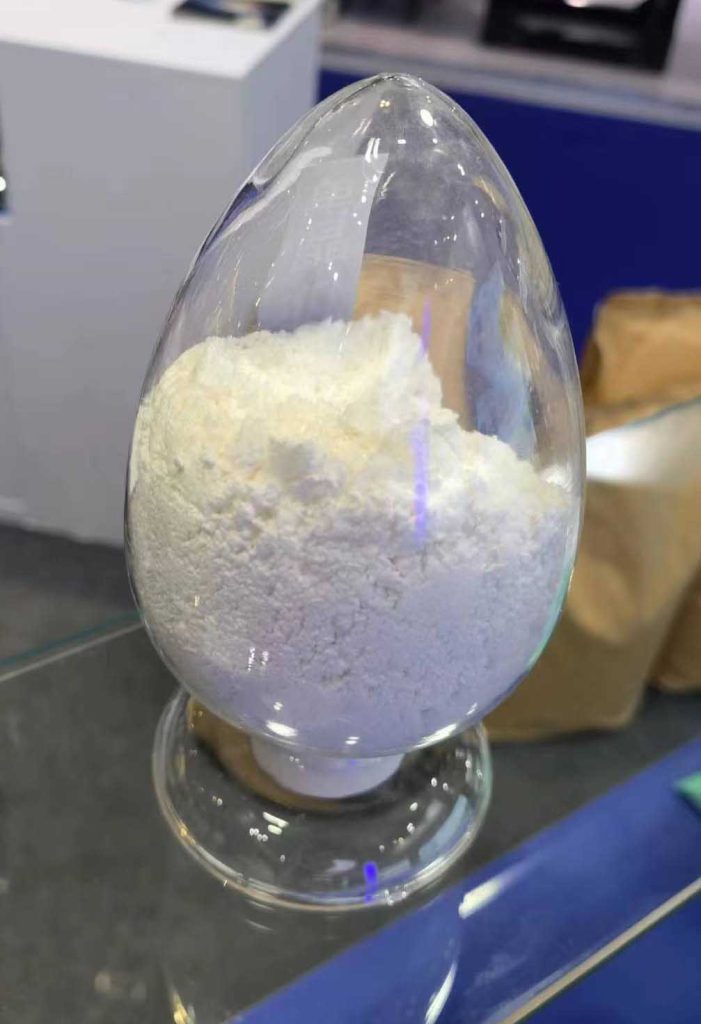

p. e. powder | Polyethylene powder

We have high-density polyethylene micro powder and low-density polyethylene micro powder | p. e. powder . First, let’s describe density polyethylene micro powder. It is a chemical additive with a melt flow index of 112 ℃ and an average particle size of 12-22 μm. It is mainly used in coatings, paints, oysters, and other fields.

This application enables polyethylene micro powder to assist in dispersing pigments and improve their hand sensitivity in coatings, making it a better dispersing pigment for the oyster industry as a carrier resin.

p. e. powder | Polyethylene powder Used for SMC,BMC

Polyethylene micro powder,usd for Pultrusion industry; as a binder, used in alkaline batteries; can also be used in rubber elastomers and other fields., is widely used in the glass waste industry.

The application of polyethylene micro powder | p. e. powder in these fields has the greatest effect of anti deflation, which is crucial for the glass industry or other industries. At the same time, it has stable mechanical properties that can resist high and low temperatures.

They ensure the electrical conductivity of the product, which helps to improve the volumetric density. At the same time, it is very compatible with the system as an anti adhesive, which can extend its shelf life and service life.

Polyethylene micropowder | p. e. powder is a white crystalline powder with a shape that resembles spherical particles. After all, its distribution is very narrow. Its main raw material is polymer particles such as polyethylene, which are refined through special processes. At the same time, there is no chemical reaction in the production process. Therefore, its functions in terms of use are very extensive.

The most obvious effect is that polyethylene micro powder is widely used as a low shrinkage agent, and it is also used as an incremental agent or hot melt adhesive in fiber-reinforced plastics. It is also widely used in extrusion processes and fiberglass.

Activated carbon filter cartridges, alkaline batteries and other fields have also been used, and it is reported that PE micro powders.

Polyethylene micro powder can also modify the physical properties of paint pigments and inks.

Polyethylene micro powder, used as a cleaning agent for alkaline battery cathodes, has a spherical structure with a very large specific surface area and a very narrow particle size distribution, with an average particle size of 10 μm.

Polyethylene alkaline adhesive. Polyethylene powder.Polyethylene micro powder.LDPE powder

Our polyethylene micro powder | p. e. powder has high chemical purity and no additives.

It can effectively reduce dust during the dry mixing process, adsorb cathodic reduction materials, reduce the occurrence of a large amount of dust during the maid process, significantly reduce waste and raw material waste.

At least we believe that the probability of occupying land is 50%, and the mechanical strength is greatly improved. It can also control compression without affecting conductivity. In terms of lubrication, it can reduce the wear rate of the mold.

The advantages of polyethylene powder.

Polyethylene micro powder can be used as an isolation agent, moisture-proof agent or of interest on the surface of polymers.

It is reported that micro powder has a dispersing effect on spraying anti-corrosion materials and pigments.

Used as an adhesive in some shielding materials.

The adhesive for the positive electrode ring of alkaline batteries is a hot melt adhesive for some high-end fabrics.

It can be used for SMC,BMC,DMC.And some additives for fiberglass molding.

In these application areas, polyethylene micro powder | p. e. powder greatly improves the stability of size, enhances mechanical properties, improves surface quality, and promotes pigment dispersion, especially in terms of low temperature resistance. It also reduces the occurrence of cracks, reduces cracking, and reduces water absorption.

The recommended addition amount is usually between 2% and 8%, and the main difference is that your usage is distinguished based on the shape of the pigment and the type of filler you produce, which accounts for approximately 1% of the entire formula.

We suggest that you fully immerse yourself in styrene, add it to the resin, and stir it at high speed to achieve a uniform dispersion effect. This can be used in the Pultrusion of other unsaturated polyesters in garbage dumps. Search for products to improve surface performance.

p. e. powder is widely used in fiberglass, alkaline batteries, activated carbon filters, low-smoke halogen-free cable materials, wood-plastic composite materials, modified plastics, powder coatings, metal coatings, pipeline anti-corrosion, water supply pipelines and other industries.

The company specializes in the production of polymer micropowder. PE powder is mainly used in SMC, BMC and pultrusion molding and is a necessary additive.

p. e. powder is reported that the appearance of micro powder is white fine powder, with an average particle size of 15-25μm.

Polyethylene micro powder can increase the toughness of products.

Reduce cracking.

Reduce the waste loss rate during the production process.

In the pultrusion process, scarring, slag shedding, peeling and other phenomena during the production process can be greatly reduced or even eliminated.

Especially in the stretching process of some large and complex profiles, the longitudinal and transverse cracks that appear can be greatly reduced, or even reduced.

p. e. powder control search to improve product size stability.

Improve the mechanical performance of the product, and even protect its low-temperature resistance.

Significantly reduce the water absorption rate of the product.

Our products p. e. powder are almost compatible with all types of SMC、BMC products and raw materials.

In different industries, we recommend using different amounts of additives. For example, the amount of pigment fillers or coatings you can use is approximately 1% to 8%, while in some waste industries, the amount of additives is approximately 1% to 5%.

For thinner products, we recommend adding 2% to thicker ones. If you want to achieve a smoother effect, such as in some situations or for large and complex profiles, we recommend using 5% to 8%.

Our polyethylene micro powder can also be used for casting and epoxy resin polystyrene, ABS, or phenolic resin, as well as some PVC numbers, which can greatly enhance their Performance.

p. e. powder has greatly improved its impact resistance and fluidity in the PVC industry.