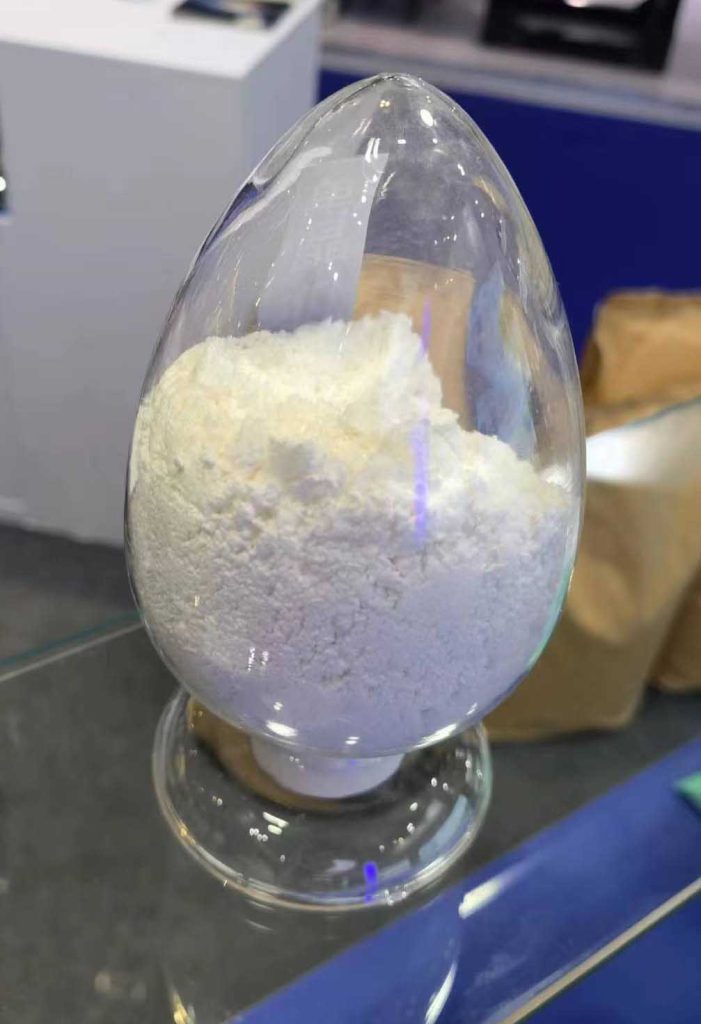

CMC Powder

CMC powder is also known as CMC gum. It is a widely used anionic, water-soluble cellulose derivative with various applications. It finds extensive use in industries such as food, toothpaste, ceramics, coatings, detergents, textiles, and even oil drilling. CMC powder serves as a versatile thickener, stabilizer, and water retention agent.

CMC power is valued for its non-toxic and tasteless nature. It presents as a flocculent white powder that readily dissolves in water for stable performance. It serves as an essential component in drilling fluid additives in oil field drilling industries.

Apart from the oil industry, CMC powder can be used as an additive in food, medicine, daily chemicals, petroleum, textiles, construction, and more. It is often referred to as medium viscosity food-grade sodium carboxymethylcellulose and functions as a versatile thickener, binder, and suspending agent in a wide range of applications. It has eco-friendly credentials, being harmless to the environment. CMC powder stands as a professional and indispensable ingredient.

What Does CMC Powder Stand For?

CMC powder is an abbreviation for Carboxymethyl Cellulose. This fine, white powder is known for its unique properties. While CMC powder is its most recognized name, you may encounter CMC powder referred to as “tylose powder” or “tylo powder.” These alternative names are essentially interchangeable with CMC powder and are used to describe the same substance with its distinctive properties.

Properties and Application: CMC Powder

As mentioned above, CMC is widely used as an additive in a lot of industries. It possesses unique and great characteristics that enables manufacturers formulate their products. Here are few of the Carboxymethylcellulose ’s characteristics:

CAS No.

The CAS number of Carboxymethylcellulose is the number 9004-32-4 is the key to distinguishing and cataloging this compound in scientific databases and industry documentation. It has the ability to alter the viscosity of solutions effectively. CMC powder, when added to a solution, significantly increases its viscosity. This property makes it invaluable in various applications.

Molecular Formula

At the heart of understanding Carboxymethyl Cellulose (CMC) powder lies its intricate chemical composition, represented by the formula [C6H7O2(OH) x(OCH2COONa) y] n. The variable ‘n’ signifies the degree of polymerization, indicating the number of repeating units in the CMC polymer chain. It reflects the length of the molecular structure, influencing the compound’s physical properties and functionality.

The variables ‘x’ and ‘y’ denote the degree of substitution in CMC. ‘x’ represents the substitution of hydroxyl (OH) groups in cellulose, typically falling within the range of 1.50 to 2.80. Meanwhile, ‘y’ signifies the substitution of sodium carboxymethyl (OCH2COONa) groups, typically ranging from 0.2 to 1.50. The sum of ‘x’ and ‘y’ equals 3.0, highlighting the balance between these two types of substitutions.

Specifications

CMC powder is known for as a powder with an appearance ranging from white to off-white. The particle size of CMC powder is a crucial parameter that impacts its performance in various applications. The specification that 95% of the particles pass through an 80-mesh sieve highlights its fine granular nature. The pH value of CMC powder is maintained within a specific range, typically ranging from 6.0 to 8.5. This controlled pH range is a critical quality parameter, ensuring the stability and compatibility of CMC with a wide range of formulations and environments.

CMC powder is devoid of any taste. It carries natural resistance to mold and mildew, making it a preferred choice in applications where product spoilage and contamination are concerns. CMC powder is non-toxic, ensuring its safety for use in various industries. Its non-flammable nature adds to its safety profile. CMC powder readily dissolves in water, forming stable solutions or dispersions, making it an ideal choice for formulations requiring a uniform texture or consistency.

Uses

CMC powder is applied and used in formulation of a lot of industrial products. Here are just few examples of where you can use CMC powder:

Oil Drilling

CMC powder is employed as a crucial component of drilling fluids. It serves multiple purposes, including viscosity control, filtration control, and shale inhibition. CMC powder helps maintain the stability of the wellbore by preventing fluid loss and controlling the viscosity of the drilling fluid. This ensures efficient drilling operations and the protection of the wellbore’s structural integrity.

Detergent

CMC powder is an essential ingredient in many detergent formulations. Its water-soluble nature allows it to disperse and dissolve effectively in water, which is vital for creating liquid and powdered detergents. CMC functions as a surfactant, facilitating the removal of dirt and stains from fabrics. It also helps in preventing redeposition of soil onto the cleaned surfaces by keeping the dirt particles suspended in the wash water. Additionally, its thickening properties contribute to the desired texture of liquid detergents.

Textile

In the textile industry, CMC powder serves as a sizing agent. It is applied to textile fibers to improve their strength and handle during weaving and subsequent processing. CMC helps control the absorption of dyes and chemicals, ensuring uniform coloration and treatment of textiles. CMC powder can act as a thickener in dye pastes, providing the necessary consistency for dyeing operations.

Painting

CMC powder finds applications in the production of water-based paints and coatings. It acts as a rheology modifier, enhancing the paint’s viscosity and flow properties. This ensures that the paint can be easily applied, spreads evenly, and adheres well to surfaces. CMC also contributes to the stability and shelf life of paint formulations, preventing settling and separation of pigments.

Ceramic

In the ceramic industry, CMC powder plays a role as a binder and plasticizer. It is added to ceramic compositions to improve their plasticity and workability, making it easier to shape and mold ceramics. CMC also helps control the drying process, reducing the likelihood of cracking or warping during drying and firing. Additionally, it can act as a suspending agent in ceramic glazes.

Packing

Typically, CMC powder is meticulously packed in three-layer paper bags with an inner polyethylene bag for added protection. The three-layer paper bag provides robust structural support, preventing the CMC powder from being easily damaged or compromised. Each bag is carefully filled to contain a net weight of 25 kilograms. This standardized packaging not only ensures convenience and ease of handling but also simplifies inventory management for suppliers and end-users.

What is CMC Powder Used For?

CMC powder plays a pivotal role as a fluid loss controller. When drilling into underground reservoirs, drilling fluids are essential for maintaining wellbore stability and carrying drill cuttings to the surface. CMC powder’s adhesive properties make it an effective tackifier in various applications. It is commonly used in industries such as construction and woodworking, where it enhances the adhesion of materials like wood, paper, or textiles. Carboxymethylcellulose also serves as a rheological additive, influencing the flow and deformation behavior of products. In applications like paints, coatings, and food products, Carboxymethylcellulose adjusts the viscosity and texture of solutions.

Is CMC a Thickening Agent?

The answer is yes. CMC powder is a versatile thickening agent widely used in various industries. Its exceptional thickening capabilities stem from its unique ability to interact with water molecules, forming a viscous solution or gel.

Is CMC a Stabilizer or Emulsifier?

The answer is both yes. Carboxymethylcellulose Sodium serves a dual role as both a stabilizer and an emulsifier in various industrial applications, including paints, oil drilling, and adhesives. This versatile compound undergoes modification to acquire unique physicochemical and functional properties, enabling its multifunctional utility. As a stabilizer, CMC plays a crucial role in maintaining the uniformity and stability of formulations, particularly in paints and adhesives. It prevents the separation of components and helps maintain the desired consistency and texture over time.

Additionally, CMC functions as an emulsifier, facilitating the mixing of immiscible substances such as oil and water. In oil drilling applications, CMC can help create stable emulsions, making it easier to manage drilling fluids and improve drilling efficiency. Moreover, CMC acts as a thickener, rheology modifier, gelling agent, and water retention agent in various products, enhancing their overall performance. Its ability to modify the viscosity and flow properties of fluids is particularly valuable in oil drilling, where precise control of drilling mud properties is essential.

Carboxymethylcellulose Sodium Broad Range of Applications

Absorbing and Holding Water

One of the primary functions of Carboxymethylcellulose is its exceptional ability to absorb and retain water. When incorporated into formulations, CMC powder acts as a moisture-retaining agent, helping products stay hydrated and preventing them from drying out. This quality is particularly critical in products like paints and adhesives.

Thickening Properties

CMC powder is renowned for its thickening capabilities. Whether in paints, oil drilling and adhesives, Carboxymethylcellulose Sodium can significantly increase the viscosity of liquid solutions. This thickening effect enhances the texture of products, providing a desirable and consistent thickness.

Binder in Formulations

As a binder, Carboxymethylcellulose plays a pivotal role in various industries, like ceramics. In tablet formulations, it acts as a binding agent, holding the ingredients together to create cohesive and easily consumable tablets. In ceramics, it assists in molding and shaping processes by providing adhesion and structural integrity.

Increasing Shelf Life

Carboxymethylcellulose Sodium’s water-retaining properties also contribute to extending the shelf life of numerous products. By retaining moisture, it helps prevent products from drying out and maintains their freshness over an extended period.

Rheology and Lubricity

Beyond the primary functions mentioned above, Carboxymethylcellulose also contributes to rheology and lubricity in various applications. It influences the flow and deformation behavior of products, ensuring that they perform as intended. In lubricants and drilling fluids, CMC powder improves lubricity, reducing friction and enhancing overall performance.